Providing An Additional Layer Of Protection

HydraTite® (Internal Joint Seal System)

Market

Power & Utilities

Challenge

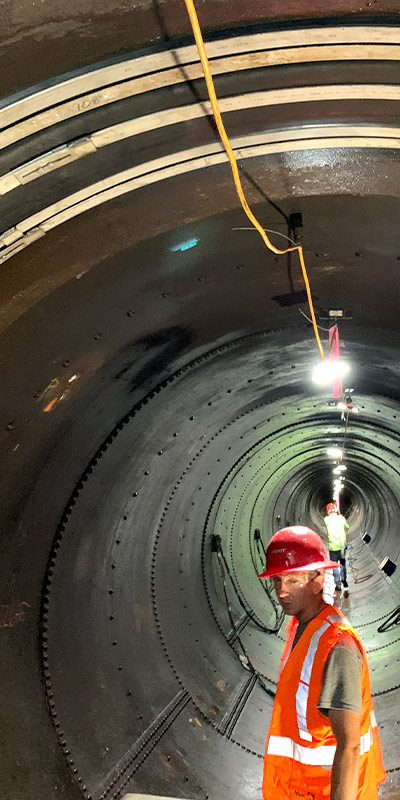

A 9’ diameter steel penstock had become separated at a riveted connection and shifting had created 1.25” of offset. The pipe was encased in concrete and within an embankment, which would complicate replacement. The repair would have to withstand a high velocity of water, approximately 9-10.5 ft per second as the pipe was part of a flowline from a hydroelectric dam.

Engineered Solution

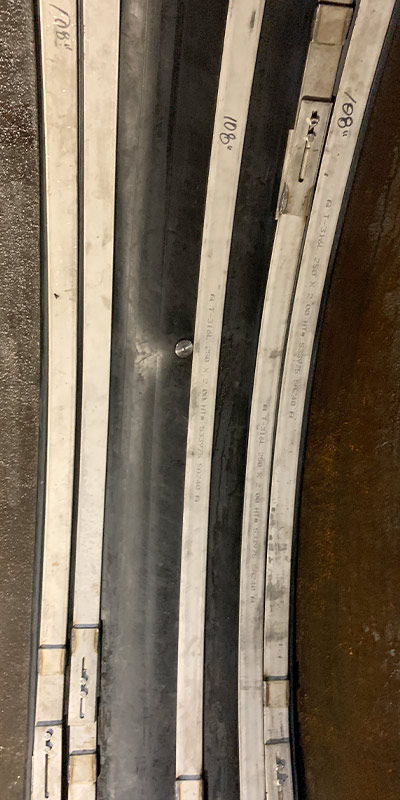

The chosen solution was multifaceted. Grout, repair plates, epoxy, and a double-wide HydraTite Seal with 5 retaining bands would be implemented together to ensure that this repair would be permanent.

Scope

This project consisted of several steps, of which several were completed prior to HydraTech’s involvement. First, the grout was injected into the joint between the encasement and penstock. Next, two overlapping repair plates were welded over the joint. Then epoxy was applied to transition the 0.75” drop off created by the plates. Then HydraTech helped instruct and install the HydraTite seal over the plates with five retaining bands holding the rubber in place. Finally, the seal was air tested and was proven to be airtight. The HydraTite installation and air test were completed in one day.

Solution

HydraTite will provide an added layer of protection for this penstock. At a fraction of the price of replacement, HydraTite will ensure there are no leaks at this joint.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature