Social Media Posts

Website Updates

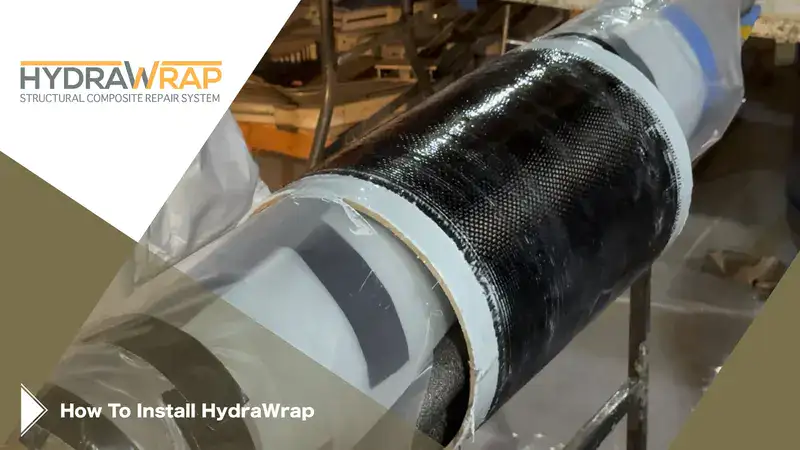

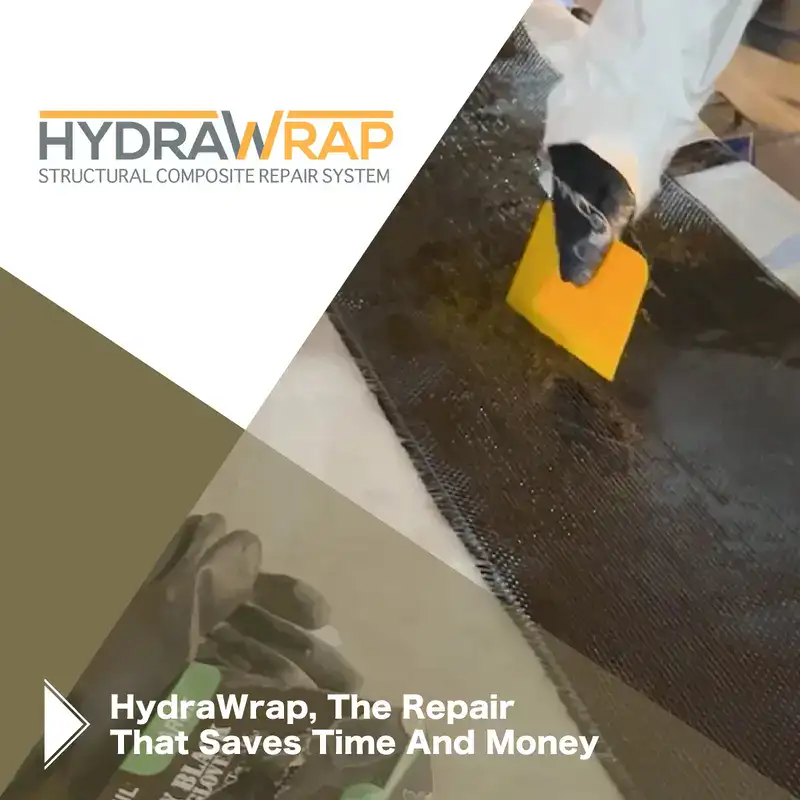

While each kit is shipped with the necessary length of fabric and epoxy best suited for the intended application, the basic application process of HydraWrap remains the same. Caleb Rutledge explains each step from surface prep to the final UV coating.

HydraWrap is a very flexible repair solution comprised of a carbon fiber fabric and epoxy. It restores aging infrastructure helping you avoid replacement..

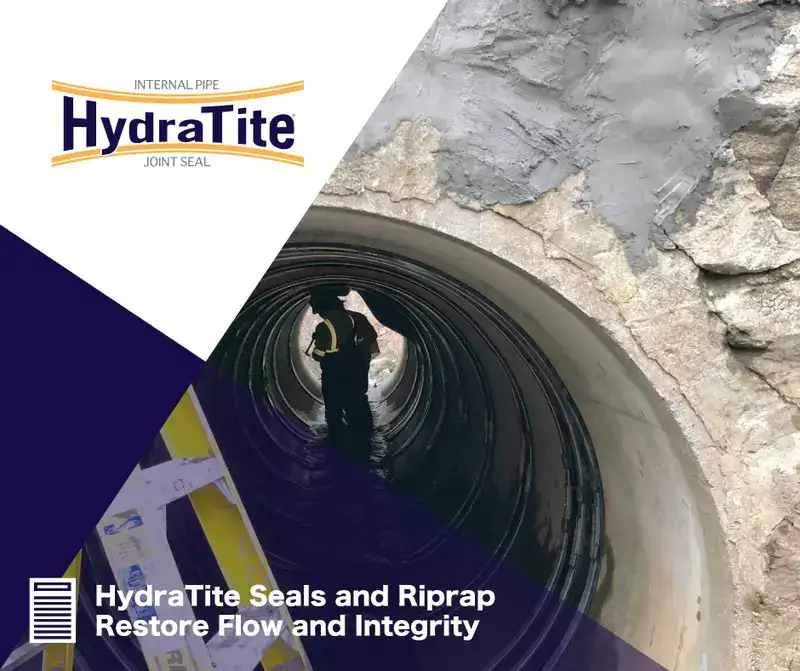

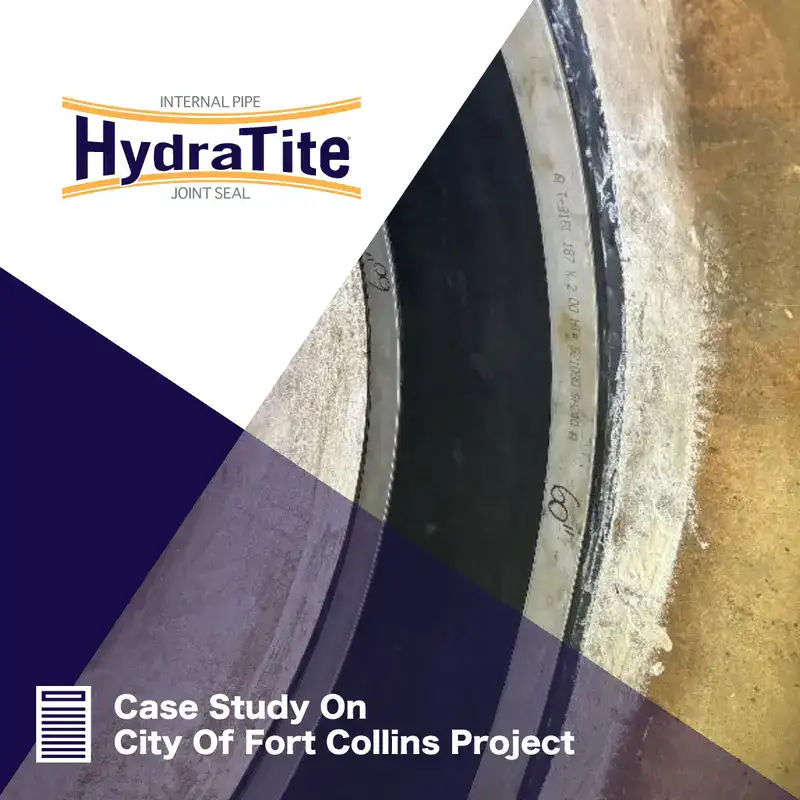

During the installation of a 20” cement-lined ductile iron pipe for a drinking water tank project in Iowa, a rolled gasket caused a leak, threatening costly project delays. HydraTech’s HydraTite Internal Pipe Joint Seal was installed in one day, effectively sealing the leak and allowing the project to resume quickly and cost-effectively.

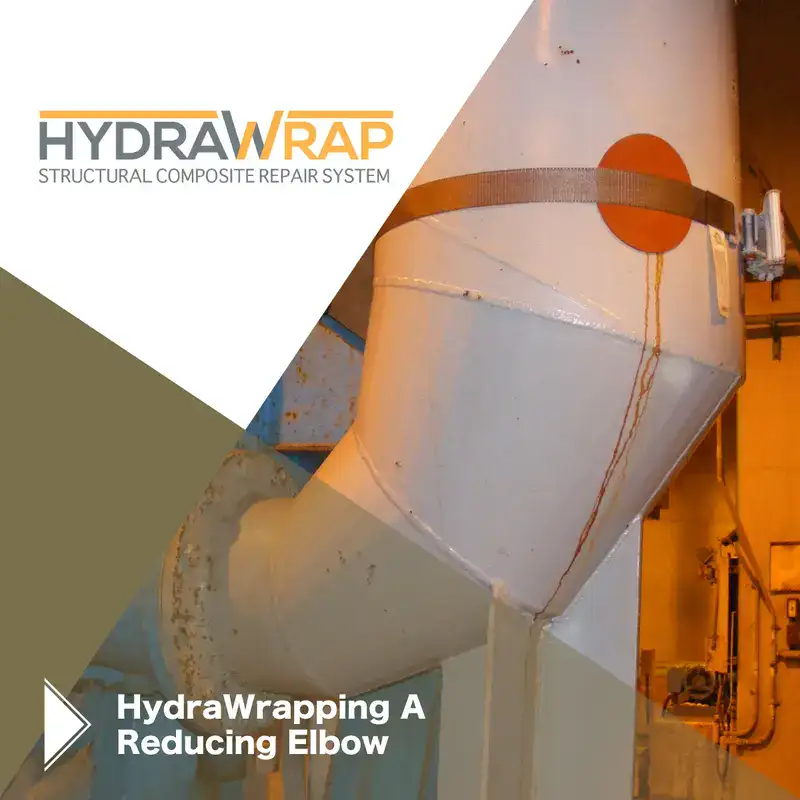

HydraWrap can conform to more than just straight runs of pipe. In this video, Caleb Rutledge explains how this repair system is applied to an elbow pipe. This highly customizable solution is quickly applied, durable, and simple to apply.

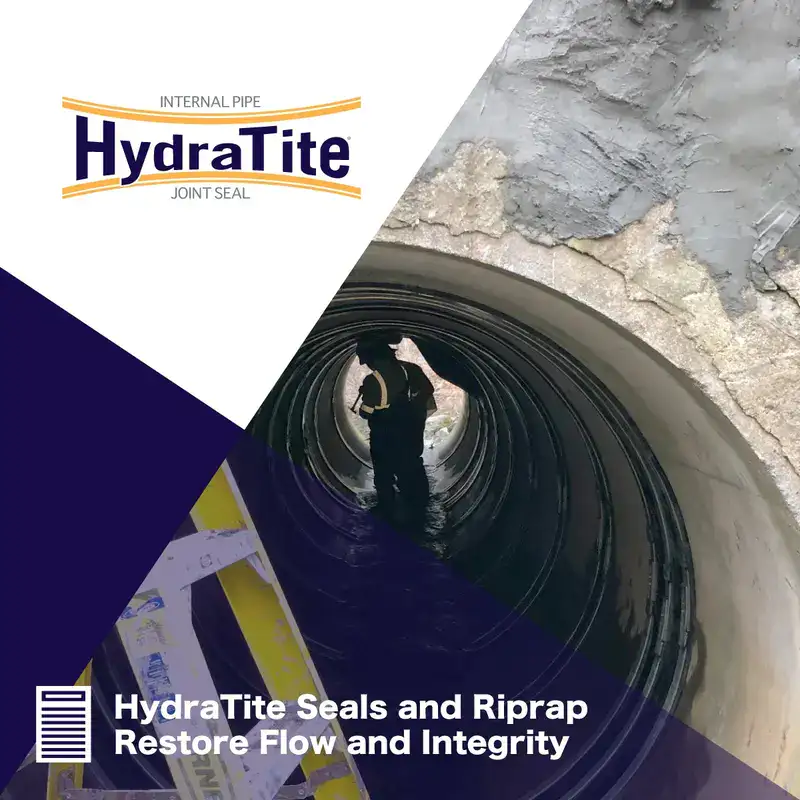

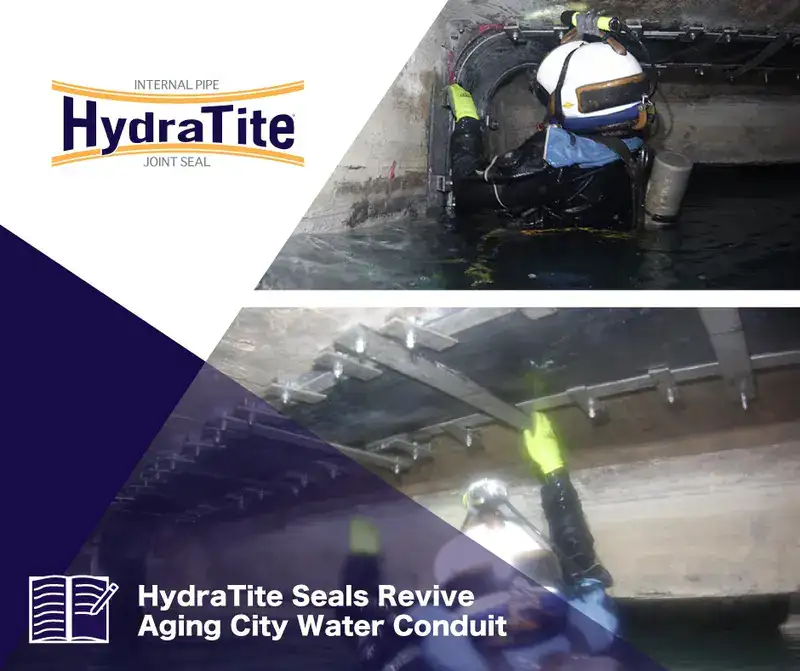

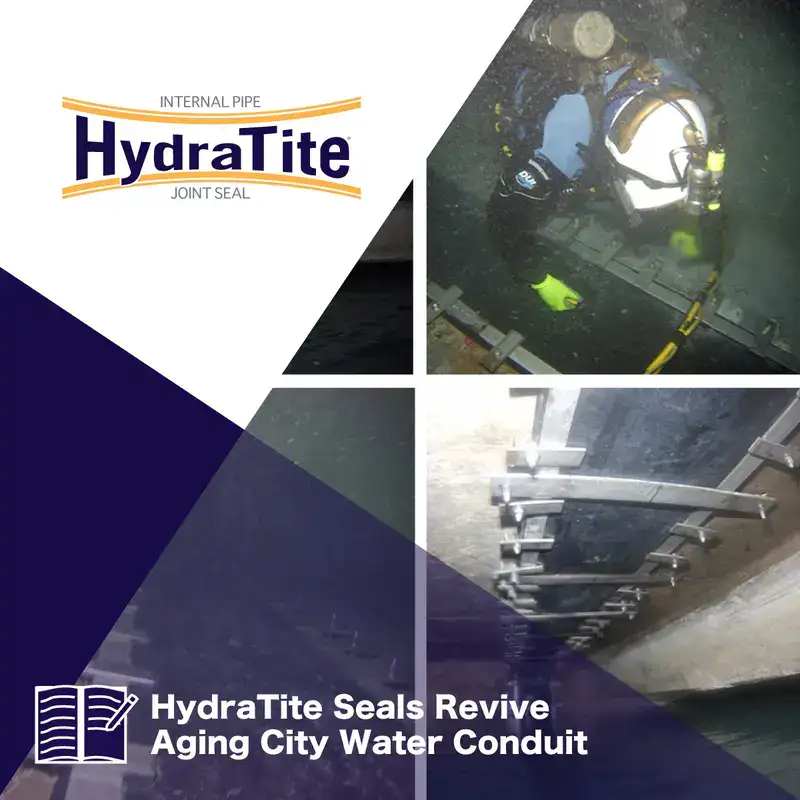

A municipal water utility in Arkansas faced a failing joint in a 43.25-inch metal pipe, causing leaks and pressure loss, which was repaired using HydraTech’s extra-wide HydraTite Internal Pipe Joint Seal. The trenchless repair, completed in three hours by two technicians, restored the pipe’s integrity without excavation, ensuring long-term protection and operational efficiency.

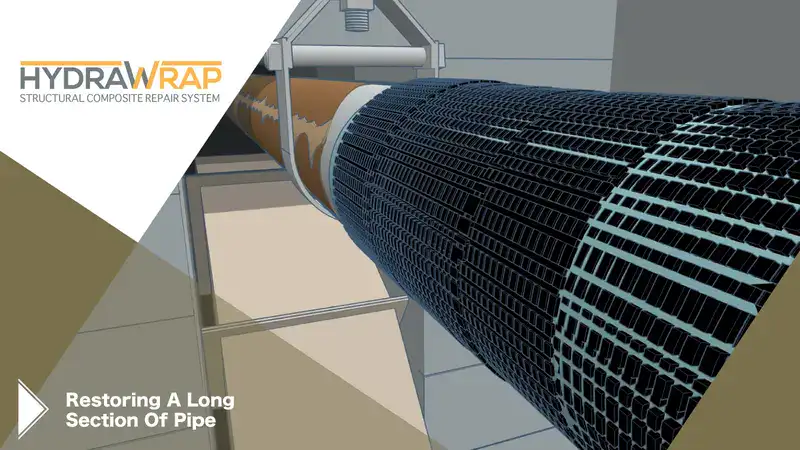

HydraWrap is a very customizable repair that can cover a larger area when it is spiraled over a pipe. This video explains exactly how the carbon fiber fabric and epoxies should be applied to ensure that the final repair has a minimum of four layers.

Especially when applied to a limited repair area, HydraWrap is a very cost-effective solution to failing pipes. Our weld kit is designed for this kind of repair and in this video, Caleb Rutledge briefly outlines the application process of a typical weld repair.

Caleb Rutledge provides this deep dive into HydraTech’s structural composite repair system, HydraWrap. Everything is explained, composition, application, versatility, and advantages. When your system becomes compromised, don’t wait for an expensive replacement part; choose HydraWrap, a repair that lasts.

Jennifer and Caleb attended the 2025 Ohio Stormwater Conference and displayed both the HydraTite and HydraLock seals. They got to speak to a lot of city personnel, including some who had already ordered our HydraTite seals for a quickly approaching project.

A carbon steel reducing elbow at a wastewater treatment plant had developed small holes and begun leaking. HydraWrap provided a cost-effective, time-efficient repair, significantly extending the elbow’s operational life.

Over the past few weeks, HydaTech has been hard at work repairing bridges across four counties in Mississippi. Our dedicated teams have tackled a range of structural maintenance tasks, ensuring the safety and longevity of critical infrastructure.