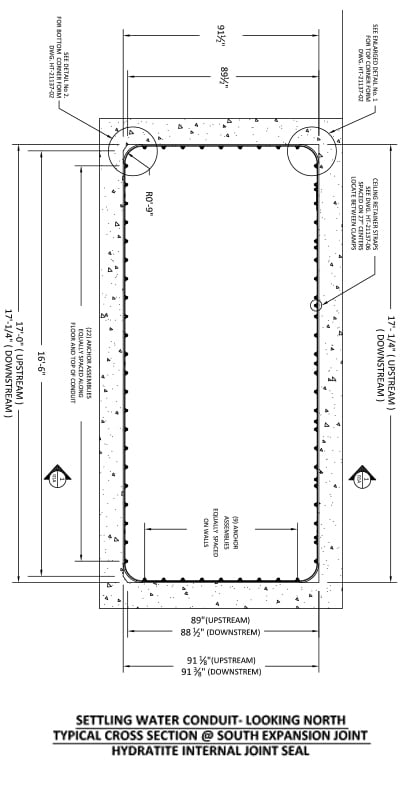

Custom Seals for 17ft by 7 ft Settled Water Conduit

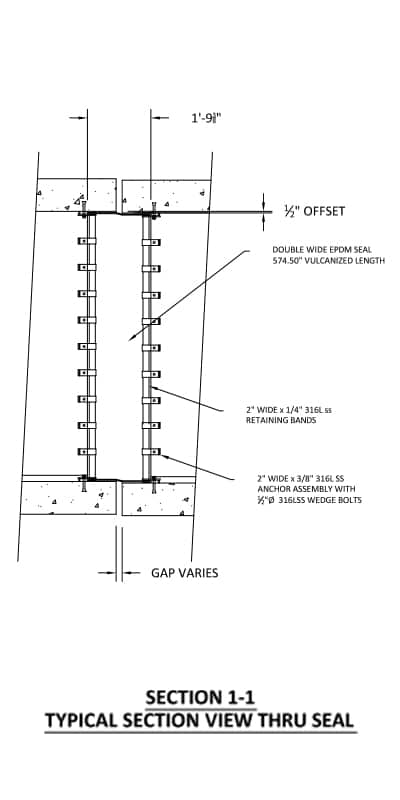

A settled water conduit was leaking at the expansion joints. This concrete conduit, originally constructed in 1941, was included in a multi million dollar upgrade to improve capacity and redundancy for the city’s water treatment plant. The repair must not hinder the continual expansion and contraction of a long section of concrete conduit while maintaining a watertight seal. The conduit was part of a water treatment system, necessitating the repair be approved to potable water. HydraTite was the chosen solution based on these requirements.

Two custom double-wide seals were made for the seventeen by seven-foot conduit. The conduit’s 90-degree corners required custom corner forms fabricated out of metal. These would help the seal adapt the conduit’s shape more effectively. Divers had to install the HydraTite seal as the conduit was mostly submerged. Not including prep work the installation took two days for each seal.