Rehabilitating A Long Section Of Pipe

HydraWrap® (Fiber Reinforced Polymer)

Market

Commercial

Challenge

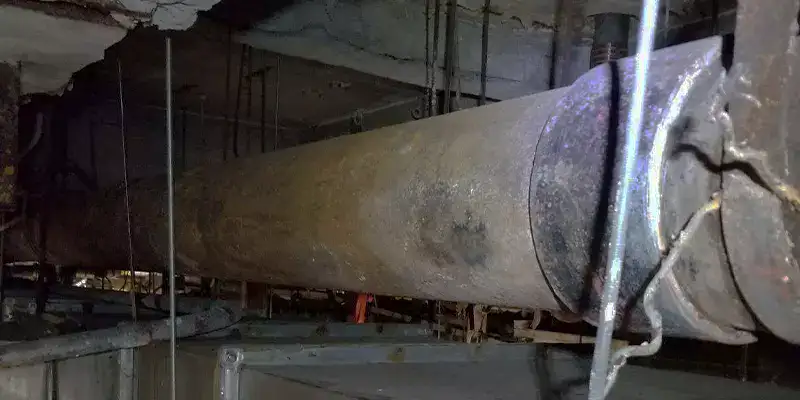

A gas main that ran through a hotel basement suffered from severe external corrosion, threatening the integrity of the pipe. The 8” pipe required an external repair to ensure that it continued to successfully supply the hotel.

Engineered Solution

They called HydraTech in to install HydraWrap, a structural composite repair system. Standard epoxy was selected for this installation.

Scope

Surface preparation was completed with nonsparking tools to remove irregularities, creating the desired surface profile for FRP installation. Primer epoxy was then applied to the prepared surface. The carbon fiber was then saturated with wet-out and applied to the primed surface. Then two layers of fabric were applied in a spiral that ran 18’. After the epoxy cured, a protective top coat of paint was added. The installation was completed in 2 days.

Solution

HydraWrap reinforced the pipe while providing a layer of corrosion protection for this gas main at a fraction of the cost and time associated with replacement.

Explore HydraWrap

Explore HydraWrap

More Products

More Products

Case Studies

Case Studies

Explore HydraWrap

More Products

Case Studies

Explore HydraWrap

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature