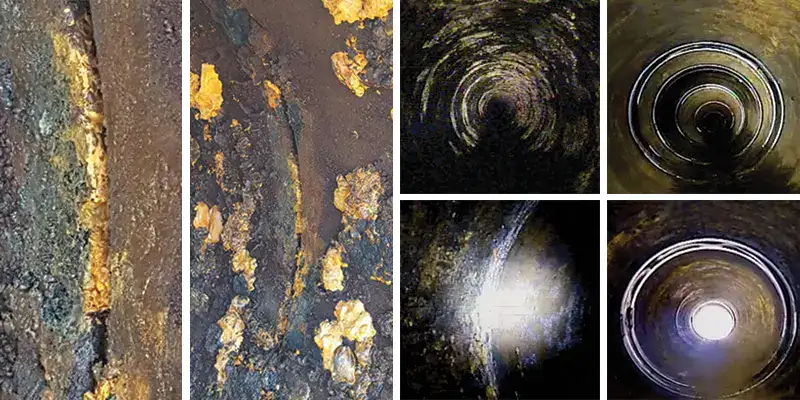

Removing Deposits From Pipe Interior To Ensure A Proper Seal

HydraTite® (Internal Joint Seal System)

Market

Drinking Water

Challenge

A new school was being built in Iowa atop pipes laid in 1937. The expected heavier use of the water main prompted the inspection of two aging 30” cast iron pipelines. Nearly 100 joints were determined as points of concern. The project owners wanted to fortify the existing pipes against infiltration without excavation.

Engineered Solution

Standard-wide HydraTite Internal Pipe Joint Seals were the selected method to rehabilitate these joints without excavation.

Scope

The project was completed in two phases. One at a time, each pipe was shut down, repaired, and then put back in use. Due to the age of the pipe, the interior had developed an extensive amount of scaling. Concrete mortar had also been applied to several joints as well. The interior surface of the pipe had to be cleared of both scaling and concrete mortar before installation to ensure that HydraTite could seal properly. 46 seals were installed in one pipeline and 49 seals were installed in the other for a total of 95 seals installed. These joints were cleaned, sealed, and air tested in just over two weeks.

Solution

In very little time, these two pipelines were fortified against infiltration and prepared for the anticipated increase in use. These nearly century-old pipes were rehabilitated without excavation and at a fraction of the cost of replacement.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature