Sealing Every Joint In These Culverts

HydraTite® (Internal Joint Seal System)

Market

DOT

Challenge

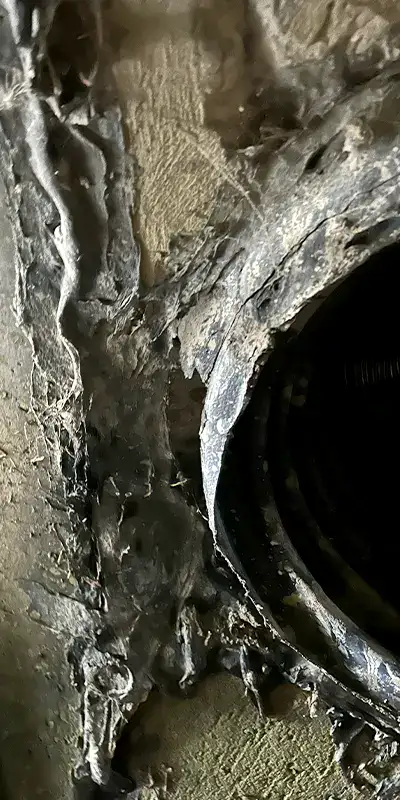

The DOT had discovered the road had slowly begun sinking above two culverts, indicating infiltration. Visual inspection confirmed that the pipe joints had become separated. Previously, some joints had been sealed using HydraTite, but budgetary restraints previously required that the most concerning joints be prioritized and only those be sealed. Now with a renewed budget, the remaining 45 joints needed to be fortified against infiltration. Just like last time, they needed a trenchless option to allow the regular flow of traffic to continue uninterrupted during the repair.

Engineered Solution

Extra-wide HydraTite Internal Pipe Joints Seals were the chosen solution to eliminate the leaks..

Scope

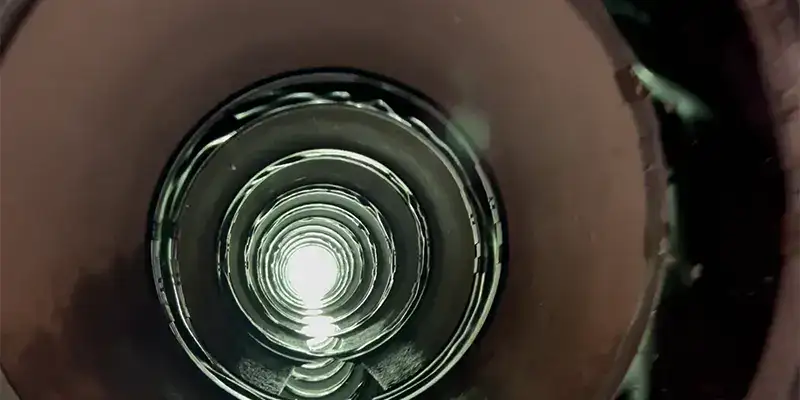

One location was a single culvert that had no previous HydraTite installations and the other was a triple culvert in which half of the joints had been sealed previously. This project involved the sealing of every remaining joint, 15 joints at the single culvert and 30 joints at the triple culvert. Both locations required circular seals, but they were sizes that were not normally stocked. The single culvert needed custom 54” extra-wide seals and the triple culvert needed 39.5” extra-wide seals. The triple culvert had a few rocks along the invert that needed to be moved and the single culvert’s invert was covered in about a foot of mud that had to be dug out prior to installation. Both pipes’ interior surfaces were in fairly good condition and required minimal surface prep before installation. One example of this prep was cutting back a smaller contributing pipe that fed into the 54” culvert. A HydraTite seal could not be installed properly because the contributing pipe protruded beyond the inner wall of the culvert. Once the joints were clean and the interior surface was uniform, the rubber was positioned over each joint. Stainless steel retaining bands were placed atop the rubber in its designated channels. A hydraulic expander was used to bring the retaining bands to pressure and a wedge was inserted to lock the bands in place. Due to other ongoing projects, the schedule was broken into two mobilizations, but 45 seals were installed in only 9 days onsite with only a crew of three onsite each day.

Solution

HydraTech custom-manufactured seals to perfectly fit these culverts and our field crew installed them quickly, providing a long-term repair for these 45 joints. The leaks were eliminated without disturbing traffic and the road will be protected against sinking any lower from infiltration.

WORKING HARD & HAVING FUN

This is one of our more simple jobs. There are only circular seals with only two retaining bands each and the job site has easy access to the culvert. Because our regular field crew was out on another assignment Will Blais was…

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature