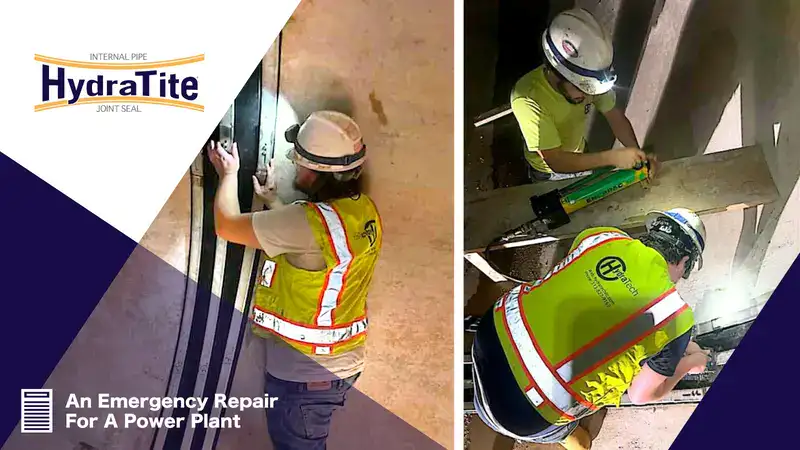

Installing During A Limited Window Of Downtime

HydraTite® (Internal Joint Seal System)

Market

Power & Utilities

Challenge

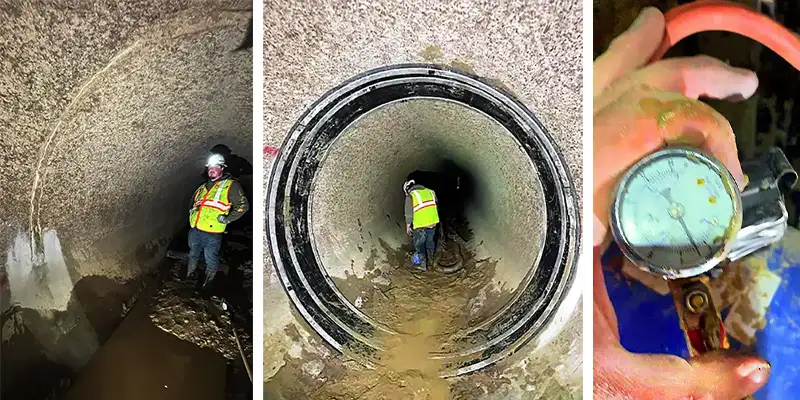

A very active leak was discovered at a single joint of a 96″ pipeline at a Texas power plant’s pump station. While HydraTech had worked at this location previously, the last project had been on a separate pipe. The leak had carried loose debris into the pipe and formed a sinkhole above. A repair was needed that could be installed fast and minimize downtime.

Engineered Solution

They chose to repair the pipeline utilizing a single extra-wide HydraTite Internal Pipe Joints Seal, manufactured with a test valve, and shipped with three retaining bands.

Scope

Our crew of only two technicians arrived during the yearly maintenance shutdown. The power plant ensured that the pipe was clear of debris and the joint was ready for installation. In a single day, HydraTech was able to install HydraTite and ensure it properly sealed the joint via an air test conducted through the test valve.

Solution

HydraTech worked within the provided maintenance shutdown window to successfully eliminate the active leak with our HydraTite seal. This project is yet another example of time and money saved by our internal pipe joint seal.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature