Restoring Structural Integrity After Seismic Damage

HydraTite® (Internal Joint Seal System)

Market

Drinking & Irrigation

Challenge

Following a major earthquake in Chile in 2010, a drinking water and irrigation system experienced structural displacement within a pipe bridge system. The seismic event caused beam movement and separation at multiple bridge joints, creating visible gaps where the exterior of the bridge could be seen from inside the structure.

The bridge consisted of dual arched aqueducts measuring 83 cm by 151 cm with a flat invert. This unique shape, combined with joint separation caused by seismic movement, allowed persistent leakage at multiple locations in this concrete structure.

Although external seals had previously been installed, they did not fully eliminate leakage under operating conditions. With a maximum operating pressure of 10 meters of water column and maximum flow velocities of 3.6 m/s, infiltration posed an ongoing risk to the plant’s reliability. Multiple joints were identified as critical points of concern, requiring a custom, internally installed sealing solution.

Engineered Solution

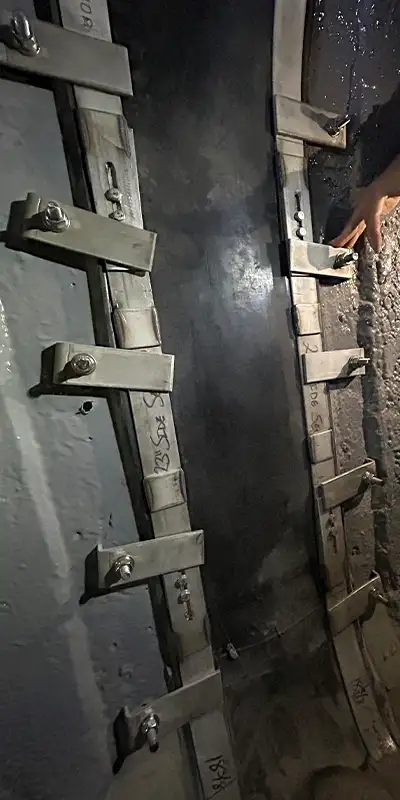

HydraTech engineered and manufactured custom HydraTite® Internal Pipe Joint Seals specifically adapted for the arched aqueduct geometry and flat invert, demonstrating the system’s flexibility beyond standard round pipe applications. The seals were equipped with two 6-piece stainless steel retaining bands.

The initial repair plan utilized extra-wide (EW) rubber seals, mechanically locked into place using stainless steel retaining bands, anchors, and hold-downs to ensure stability under flow and pressure conditions. The seals were designed to conform to the non-cylindrical shape while maintaining full circumferential contact across the joints.

Scope

HydraTech manufactured and supplied the extra-wide HydraTite® seals. Constructora Rio Maule installed these seals across the 18 sections of the bridge. After installation, it became apparent that one joint exhibited significantly greater separation than anticipated, exceeding the effective coverage of the extra-wide seal.

To address this condition, HydraTech quickly manufactured a double-wide HydraTite® seal to span the increased joint gap. The replacement seal was installed and secured using the same mechanical retention system, restoring the severely displaced joint.

Solution

The customized HydraTite® sealing system successfully eliminated leakage at all repaired joints despite their non-standard geometry. By adapting seal design to an arched aqueduct with a flat invert and rapidly supplying a wider solution when conditions demanded it, HydraTech restored watertight integrity where external sealing methods had failed.

This project demonstrated HydraTite®’s ability to deliver flexible, field-responsive, trenchless sealing solutions for critical infrastructure, even in irregular shapes.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature