An Emergency Repair For A Power Plant

HydraTite® (Internal Joint Seal System)

Market

Power & Utilities

Challenge

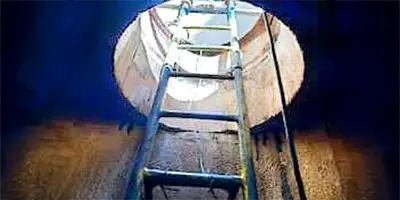

A power plant’s pump station in Texas discovered its 132″ pipeline had become compromised. A leak was found at a single joint and a repair was needed that could be implemented quickly, minimizing downtime.

Engineered Solution

A single extra-wide HydraTite Internal Pipe Joints Seal with three retaining bands and a test valve was the chosen targeted and trenchless repair.

Scope

The power plant personnel ensured that once our four-man crew arrived, the pipeline was out of service and the joint was fully prepared for installation. Once on-site, our crew positioned the rubber over the joint, placed the retaining bands over the rubber, and expanded them with the hydraulic expander. The pressure was dispersed by tapping the retaining bands and when the correct pressure was reached, wedges were inserted into the retaining bands, locking them in place. Finally, the test valve was opened and air was pumped behind the rubber. A soapy water solution was sprayed on the outer edge of the entire seal and inspected for bubbles that would indicate escaping air. The seal passed the air test and the valve was closed. The whole process was completed in a single workday.

Solution

HydraTite eliminated the leak efficiently and within a short window of downtime provided by the power plant. The project was such a success the power plant called us back to repair another pipeline the next year.

Sister Project At The Same Location

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature