Custom Seals Installed Underwater

HydraTite® (Internal Joint Seal System)

Market

Water & Utilities

Challenge

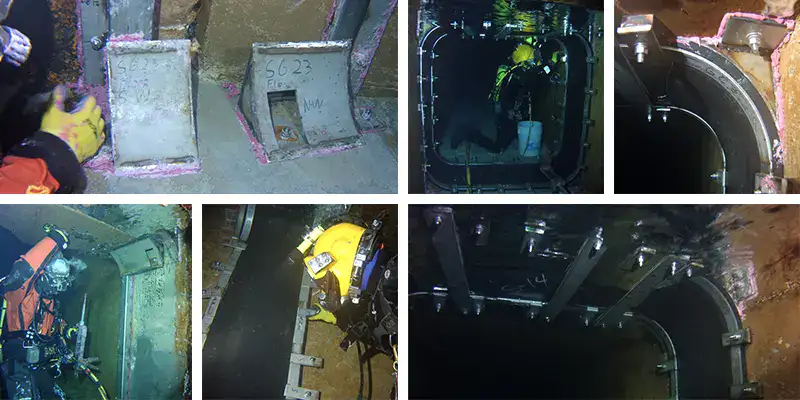

A drinking water facility in northwest Ohio discovered leaks in the joints of submerged box-shaped chambers. The chambers were of various sizes and were part of the facility’s filtered water conduit system. The chambers did not all run in a straight line so the repair would need to accommodate joints where one section joined another at a slight angle. The repair also needed to be installed underwater as they did not intend to shut down the system.

Engineered Solution

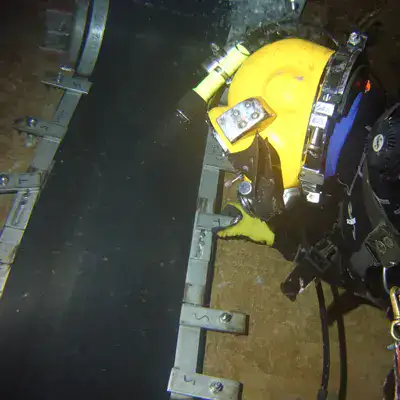

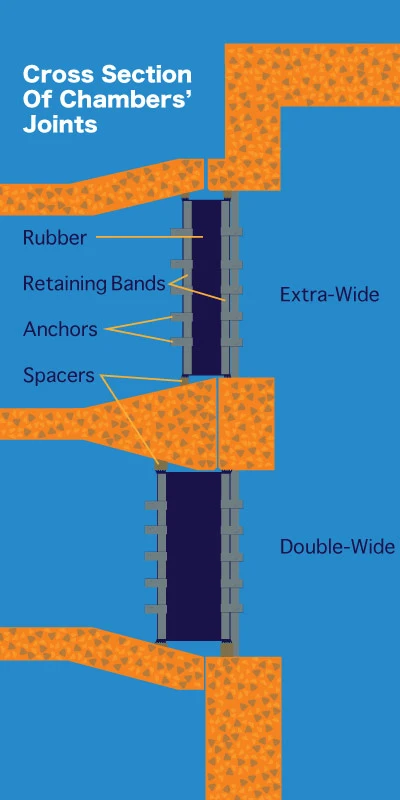

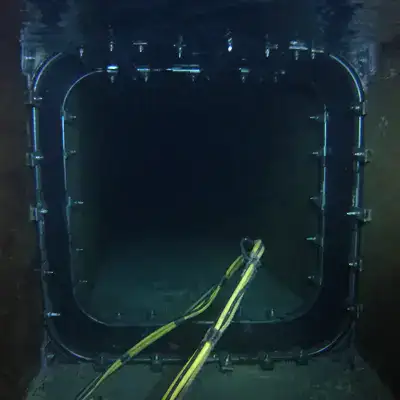

HydraTite Internal Pipe Joint Seals were the chosen solution to eliminate leaks as they can be installed underwater. HydraTech custom-manufactured steel corner forms, ceiling bars, anchor clamps, retaining bands, and rubber to perfectly fit the leaking chambers. Extra-wide seals were made for chambers with equivalent diameters of 63.5”, 61.75”, and 70.75”. Double-wide seals were made for 61.25” and 63.5”.

Scope

In instances where the chambers did not all run in a straight line, divers installed spacers to aid the rubber in the transition over the joint. Then the corner forms were installed and sealed. Next, the rubber was positioned over the joint, and the retaining bands were placed in the rubber’s designated channels. After that, anchors were inserted around the perimeter of the rubber on either side. Then anchor plates were loosely attached to the anchors over the rubber and retaining bands. Each expansion point was then brought to pressure and the retaining bands were then locked in place. The anchor plates were then tightened down. The ceiling bars were installed at the joints that required them. Finally, the anchors were trimmed. 9 seals were installed in stages over about 4 weeks.

Solution

This conduit system was rehabilitated without shutting down the system. HydraTite offered a solution at a fraction of the cost and time associated with dig and replace methods.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature