Defective Welds In A Hydroelectric Dam’s Water System

HydraWrap® (Fiber Reinforced Polymer)

Market

Power

Challenge

Various pipes in a water system in a hydroelectric dam had begun leaking. Defective welds were discovered to be the source of these leaks. A permanent solution was needed that was flexible enough to fit pipes of different sizes and shapes.

Engineered Solution

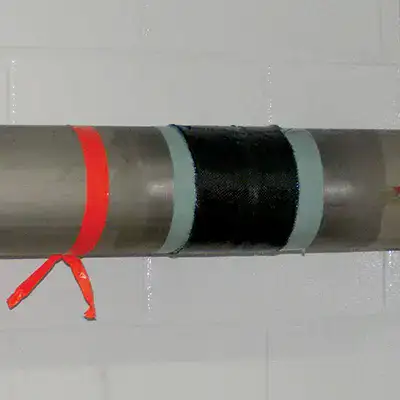

To eliminate the leak quickly and avoid costly replacement, a composite repair was chosen, 6” HydraWrap fabric with the standard epoxy.

Scope

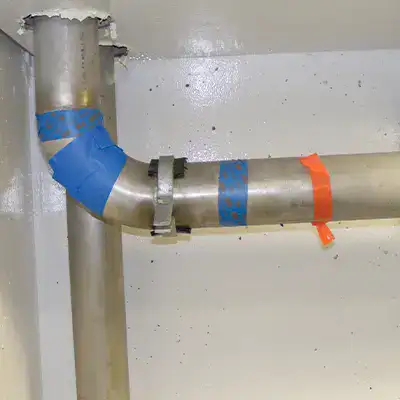

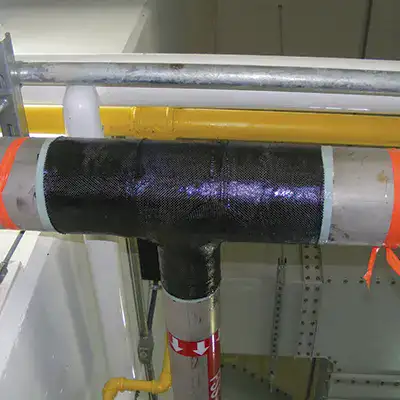

Mechanical surface preparation was used at each location to ensure proper adhesion. The length of the repair was then marked using tape. Primer epoxy then coated the pipe’s exterior. Carbon fiber fabric was wet out and then applied to the pipe. Some repairs required only 2 layers while other larger pipes or pipes with a higher operating pressure were wrapped with up to 4 layers. Nearly 100 points in this system were rehabilitated utilizing HydraWrap in roughly a month.

Solution

HydraWrap provided a long-term solution that was able to accommodate elbows, flanges, tee fittings, and straight portions of pipe. This repair was applied faster than replacement and at a fraction of the cost.

Explore HydraWrap

Explore HydraWrap

More Products

More Products

Case Studies

Case Studies

Explore HydraWrap

More Products

Case Studies

Explore HydraWrap

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature