Eliminating Leaks & Preventing More From Forming

HydraTite® (Internal Joint Seal System)

Market

DOT

Challenge

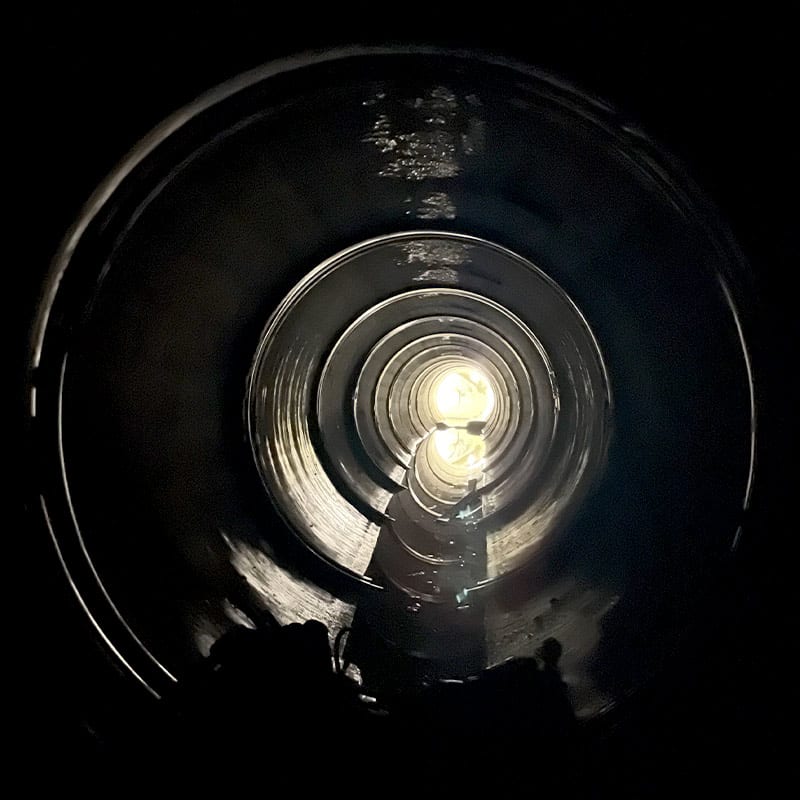

A bridge was under reconstruction as part of a larger FHWA-funded project that aimed at updating roughly half a mile of a state route. The bridge was to be worked on in sections to avoid stopping all traffic. During this project, 3 active leaks were found in the 72” reinforced concrete pipe that was part of a reservoir below the bridge. In addition, several joints were experiencing separation. Previous grout repairs had begun to fail. In total,16 joints raised concerns of leaks or developing leaks soon. There were also lift points in the middle of 22 sections of pipe, each located at the crown of the pipe. 10 of these lift points were leaking despite previous mastic repairs. A repair was sought that would allow traffic to continue to flow on the above bridge.

Engineered Solution

The client decided HydraTite would best fit the needs of the joint repairs as it is a trenchless solution that would not affect the traveling public. 16 of the two-piece double-wide HydraTite seals were specified to seal the joints. Grout, epoxy resin, and fast-drying hydraulic cement were specified for the concrete point repairs.

Scope

Failing mastic was first removed from the lift points. Compromised concrete near the lift points was chipped away and dusted. The 10 leaking lift points had fast-drying hydraulic cement applied to them. Then the newly exposed rebar was coated in an epoxy resin for protection. Next, grout was pumped into the void through a form that would hold the grout in place while it cured. The joints were then inspected and a 4th leaking joint was found. These 4 leaking joints had their grout replaced and all 16 joints then had HydraTite seals installed over them. The entire process took 3 weeks.

Solution

HydraTite provided a lifetime of protection against infiltration and exfiltration by eliminating the active leaks and protecting all the joints from future leaks. The 22 lift points were covered. HydraTech meticulously ensured the rehabilitation of this system utilizing only a fraction of the time and cost of replacement.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature