Rehabilitating 24″ Pipe With Separation At The Joint

Market

DOT

Challenge

During an inspection, VDOT discovered separation at 7 RCP joints. They opted to rehabilitate this 24” diameter pipe rather than replace it to avoid disrupting the park and ride area above the pipe.

Engineered Solution

Initially, HydraTite Internal Pipe Joint Seals were selected as the trenchless repair for all 7 joints, but upon further review, it was decided that HydraTite would be installed on 6 joints and HydraWrap would be installed on the joint with the most severe separation.

Scope

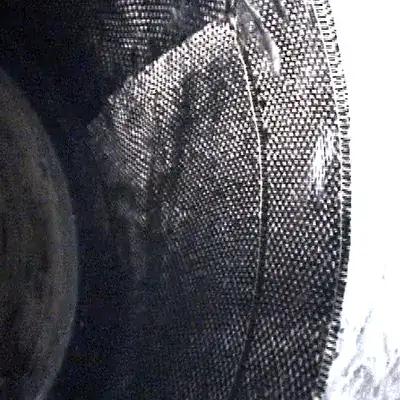

Three people were on this project and step one was cleaning the pipe. Then 6 standard-wide seals were installed with single-piece bands. It was at this point the final joint was reevaluated and the separation was determined to be too severe for the double-wide seal. A HydraWrap weld kit with standard epoxy was ordered for installation the next day. The interior surface of the pipe was dried to ensure the epoxy would cure correctly. Next, the four layers of carbon fiber fabric were saturated with wet out and applied. The cleaning and installation of the six seals were completed in a day and the HydraWrap was applied the next day.

Solution

A small crew was able to rehabilitate the pipeline in only two days despite the necessary onsite changes to the initial plan. The project was completed in a fraction of the time and at a lower cost than required for replacement.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature