HydraTite® (Internal Joint Seal System)

HydraWrap® (Fiber Reinforced Polymer)

Restoring Pipe, Inside And Out

Market

Power & Utilities

Challenge

Leaks had been discovered in a circulating water system. The points of concern were in prestressed concrete cylinder pipe and steel pipe in sizes ranging from 92” to 138” in diameter. Internally, there were signs of spalling and at one joint portions of the steel bell had become exposed.

Engineered Solution

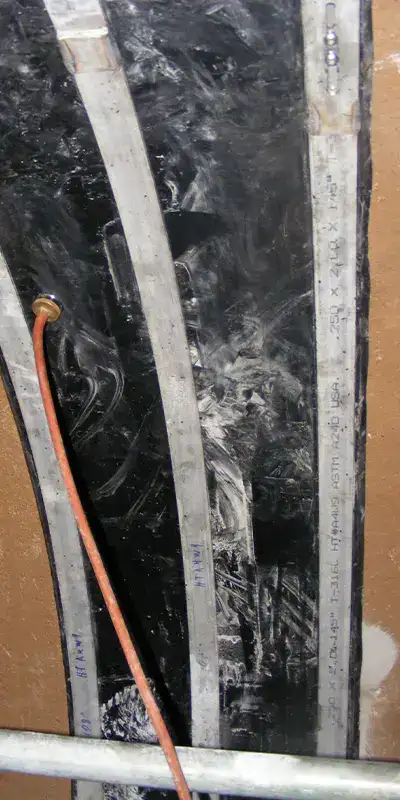

HydraTite internal pipe joint seals were chosen to remedy the joints with interior damage and the HydraWrap Structural Composite Repair System was to be applied on the exterior of the compromised joints.

Scope

The interior surface was prepared ensuring a uniform and smooth surface for sealing before the arrival of the four HydraTech technicians. Inside the pipe at a 45-degree elbow, scaffolding was set up and grout was used to fill two joints. The double-wide HydraTite rubber seal was positioned over each joint and the three retaining bands locked the seals in place. The actual installation of the 108” and 120” seals took roughly two hours each. Finally, the seals were air tested. Over the next two days, the HydraWrap was applied to the exterior of seven joints. Exposed reinforcement bars were cut away and loose concrete was removed. Then the exterior surface of these joints was pressure washed. Hydraulic cement was then applied to the joint to restore the surface profile, creating a smooth transition from one pipe to another. Epoxy was applied to the exterior of the joints, the carbon fiber fabric was saturated in wet-out epoxy and then two layers were applied to the exterior of the joints. Four of the 92” joints, two of the 124” joints, and one 138” joint were wrapped.

Solution

In three days a crew of four was able to eliminate leaks during the shut-down window and restore this system at a fraction of what replacement would have cost. These joints will be protected for a lifetime.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature