Repairing A Recirculating Pump Line

Market

Power

Challenge

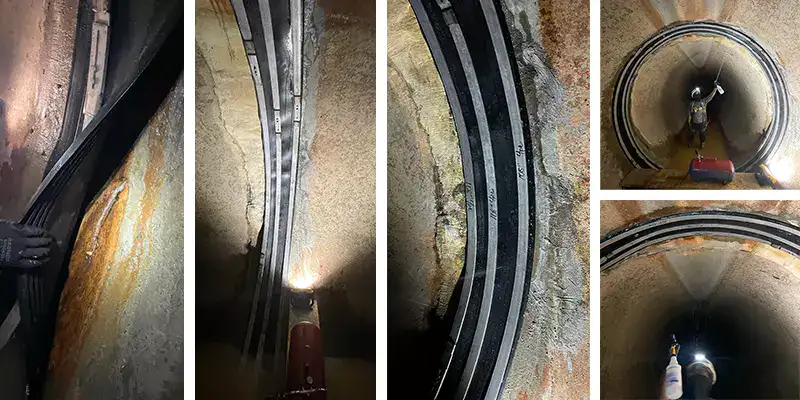

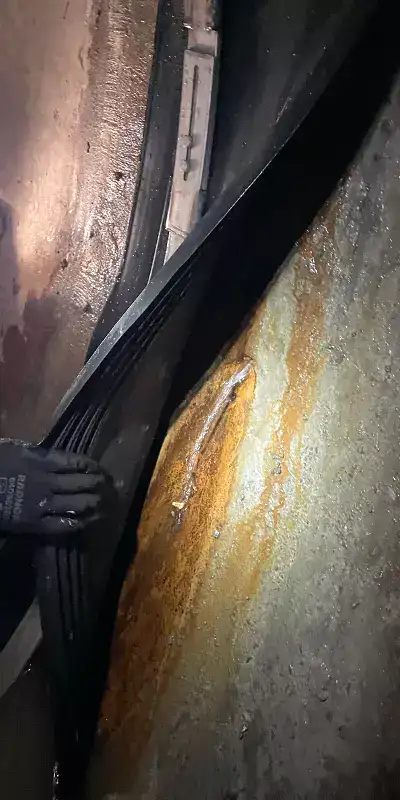

A power plant in Texas discovered a leak in their recirculating pump line. They were looking for an internal repair for this 108” prestressed concrete cylinder pipe (PCCP). The repair would have to withstand head pressure when the system was shut down for maintenance in the future. Access to the pipe was through an approximate 24” entry point.

Engineered Solution

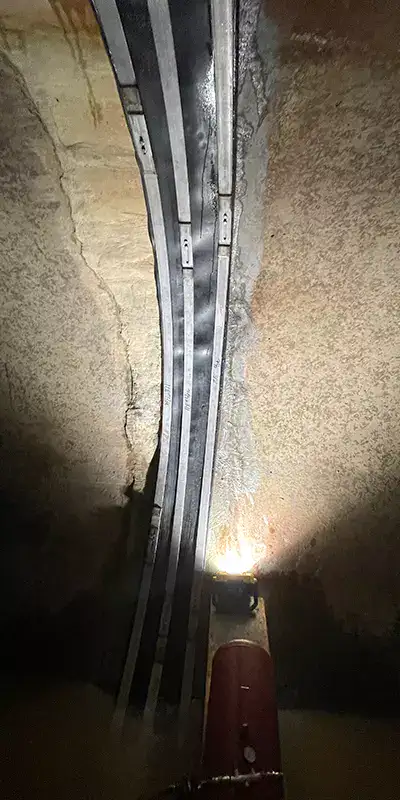

A HydraTite seal was chosen as the solution. This extra-wide seal would be installed with three of the four-piece bands to accommodate the head pressure. The retaining bands being in four pieces would allow it to easily go through the 24” entry point.

Scope

The system was shut down and sump pumps kept water low. HydraTech Field Services positioned the rubber over the leak and locked it in place with the retaining bands. Then air was pumped behind the rubber and a soapy water solution was sprayed around the outer edge of the rubber. It was inspected for bubbles that would indicate escaping air. Everything from installation to passing the air test was done in only about two hours.

Solution

The HydraTite® internal seal was installed, the leak was eliminated, and this quick installation saved the power company extended downtime.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature