Stopping Contaminants From Entering The Pipe

HydraTite® (Internal Joint Seal System)

Market

Stormwater

Challenge

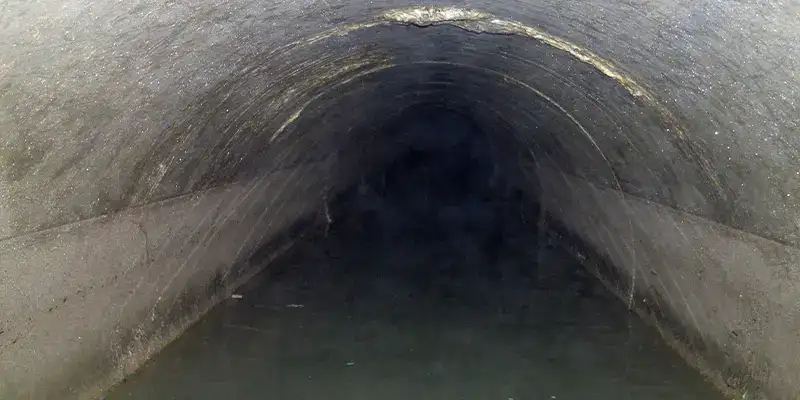

A steel mill became concerned with their stormwater pipeline. Testing the discharge at the end of the pipe revealed that contaminants had infiltrated the pipe through compromised joints. Upon visual examination, it became apparent that debris such as gravel had worked its way into the pipe as well. A trenchless solution was preferable.

Engineered Solution

To avoid the high cost and inconvenience of dig and replace options, extra-wide HydraTite seals were chosen to repair the points of concern.

Scope

The first couple of weeks were focused on cleaning out the debris and scrapping away calcium from the surfaces near the joints that needed to be sealed. Over the next week, 66 seals were installed.

Solution

In only three weeks the joints were sealed and additional testing revealed that the contaminants were no longer entering the pipe. This trenchless solution was cost-effective and time-efficient.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature