Terminating A Cured-In-Place Liner

HydraTite® (Internal Joint Seal System)

Market

Wastewater

Challenge

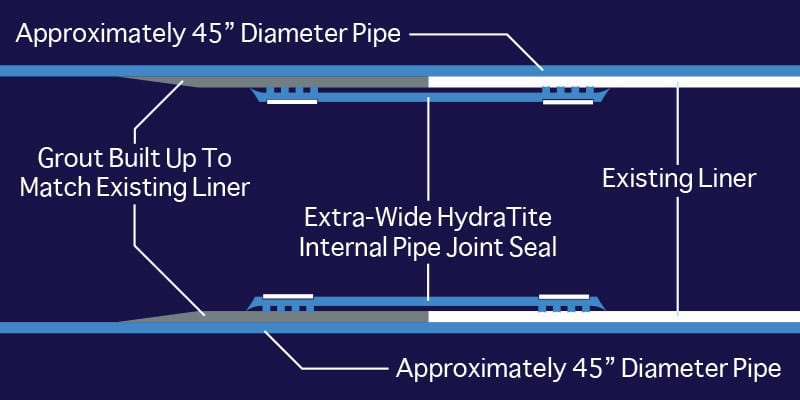

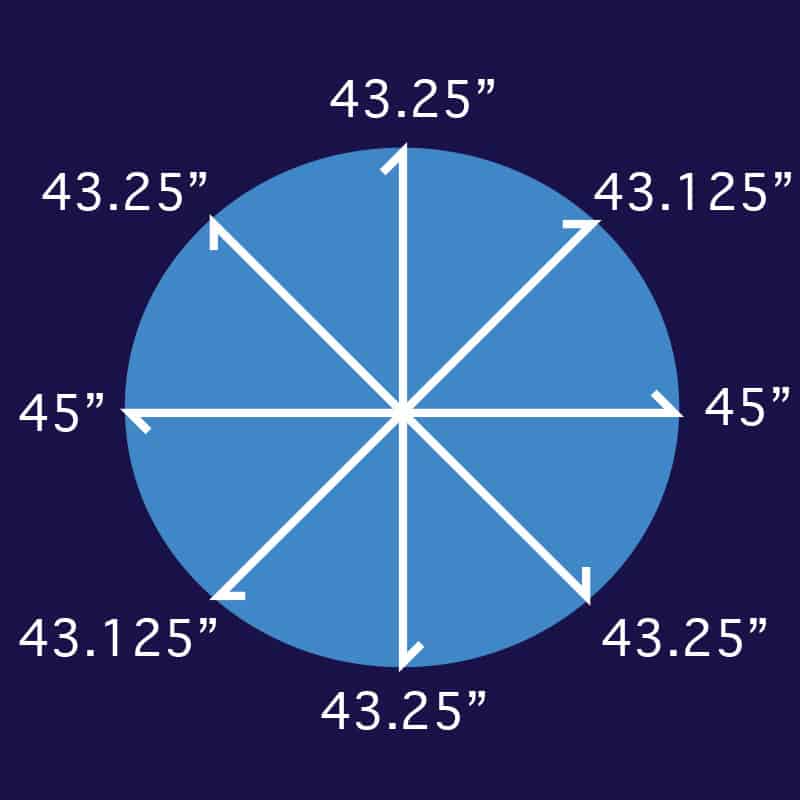

A pressurized sanitary line that was approximately 45″ in diameter had been repaired with CIPP (cured in place liner), but water had started to backtrack behind the liner. Replacement would be time-consuming and expensive, and coating or grouting behind it would not provide for a long-term repair.

Engineered Solution

The engineer had reviewed several point repair solutions such as coatings, grouts, and engineered wraps, however, due to the changes in the temperature of the fluid in the pipe and the pressure in the line, the engineer needed a long-term, flexible solution to eliminate backtracking behind the line. After talking with our engineering team, the engineering specified a HydraTite End Seal, a trenchless mechanical solution designed to stop the backtracking water that was jeopardizing the integrity of the liner.

Scope

The liner had some wrinkles that necessitated the liner be cut back 12” to provide a smooth sealing surface. Grout was then applied to make the non-lined pipe’s profile flush with the lined pipe. Once the grout had cured, HydraTech oversaw the installation of the custom 44.15” extra-wide HydraTite seal with 2 of the 2-piece retaining bands over the end of the liner. The seal’s installation took one day.

Solution

HydraTite protected the integrity of the CIPP which in turn prolonged the life of the pipe. HydraTite prevented the need for replacement which saved the client time and money.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature