Two Box Seals Installed In Vertically Stacked Box Flumes

HydraTite® (Internal Joint Seal System)

Market

Drinking Water

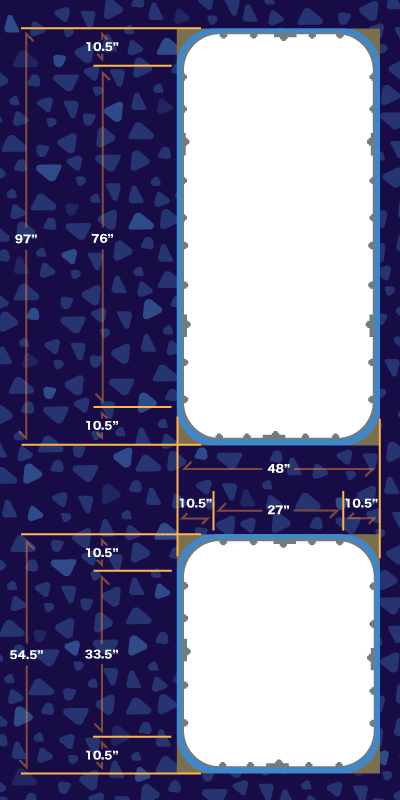

Previous repairs were failing and an active leak threatened the integrity of a water facility in Kentucky. The affected joint ran through two box-shaped flumes that were stacked vertically. One was 48” by 54.5” and the other was 48” by 97”.

Engineered Solution

HydraTech provided custom-made HydraTite seals with anchors and corner forms for both joints.

Scope

Upon arrival, HydraTech technicians discovered that the corners of the flume were not perfectly sharp 90-degree angles. The result was that the corner forms would not sit flush with the walls. HydraTech chipped out the corners and applied concrete as needed to allow the corner forms to sit properly against the walls. All other abnormal indents and raised portions were smoothed out with chipping and concrete as well. Next, the corner forms were installed, the rubber and steel were positioned over the joint, and the anchors were installed. The retaining bands were expanded and the anchor plates were tightened onto the bands. Finally, a sealant was applied to the edge of the corner forms.

Solution

HydraTech provided customized seals to eliminate leaks in failing joints and the field crew adapted the installation plan to accommodate the irregular corners. These two joints will be fortified against leaks for much longer than the previous repair.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature