Stabilizing Roadway Drainage with HydraTite

HydraTite® (Internal Joint Seal System)

Market

DOT

Challenge

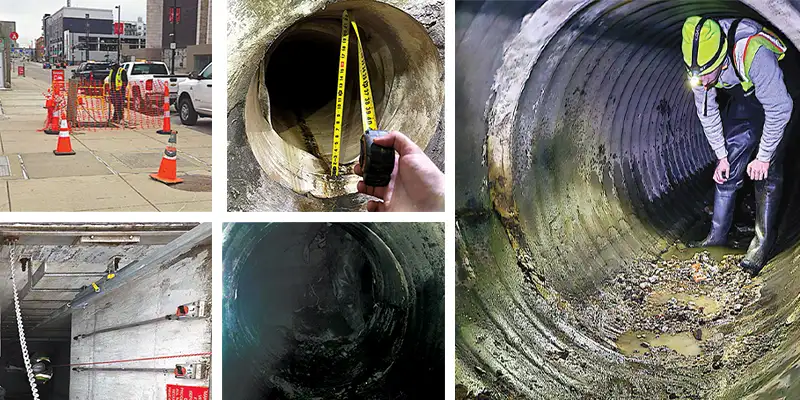

The Ohio Department of Transportation (ODOT) identified infiltration issues at multiple joints within stormwater drainage pipes beneath a roadway in Cincinnati, Ohio, located near HydraTech’s manufacturing facility and headquarters. Compromised joints in a 48-inch corrugated metal pipe (CMP) and a 23-inch concrete pipe were allowing soil and sediment to enter the system, contributing to buildup at a downstream pump station and resulting in minor roadway sag above.

The smaller pipe had previously been lined, but the liner was now failing and required localized rehabilitation. In addition, the age of the 23-inch pipe and imperfections in its original manufacturing meant the joints were not perfectly cylindrical. ODOT needed a flexible, trenchless solution to stop infiltration, stabilize the drainage system, and protect the roadway without excavation or traffic disruption.

Engineered Solution

HydraTech recommended the HydraTite® Internal Pipe Joint Seal system, engineered to adapt to irregular pipe geometries and provide long-term infiltration control. Double-wide EPDM rubber seals, paired with three, two-piece stainless steel retaining bands, were selected to accommodate the varying pipe conditions.

Scope

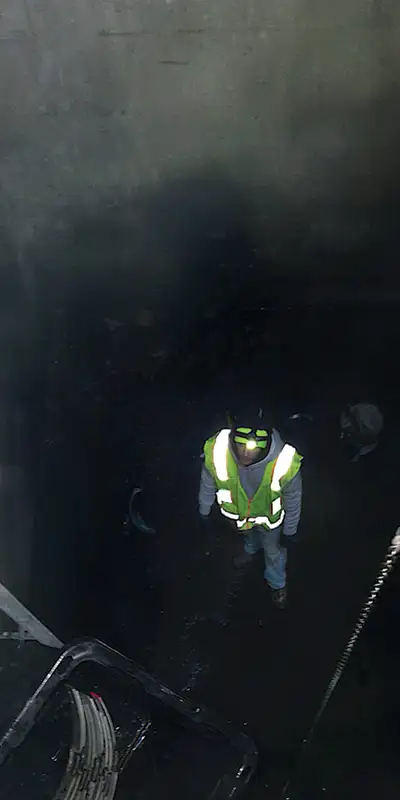

The pipes were cleared of debris prior to HydraTech’s arrival, allowing immediate access for installation. A three-person HydraTech field crew completed all work over two working days.

In the 48-inch corrugated metal pipe, one joint contained a concrete patch over the invert that required removal via jackhammer prior to installation. Due to the shallow corrugation depth, a limited amount of Pro-Stick® was applied to low points in the corrugation to unify the surface and ensure smooth, continuous sealing. Six joints were sealed in this pipe along an 80-foot span.

Two joints were sealed in the 23-inch concrete pipe, all within 10 feet of the access point. Installation required working on an incline, and any liner protrusions that could interfere with seal placement were removed. HydraTite® seals demonstrated their flexibility by conforming to offset and misaligned joints, maintaining full circumferential contact despite the challenging geometry of the pipe.

Solution

All eight joints were successfully sealed, eliminating infiltration and preventing further sediment migration into the drainage system. The trenchless HydraTite® installation stabilized subsurface conditions, protected the roadway above, and restored reliable drainage performance, without excavation or extended disruption. This project was completed quickly and highlighted HydraTite®’s adaptability, even in tight access conditions and non-uniform pipe profiles.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature