Sealing Critical Pipe Transitions to Stop Infiltration

HydraTite® (Internal Joint Seal System)

Market

DOT

Challenge

An Ohio Department of Transportation (ODOT) inspection identified active infiltration at the crown of a stormwater pipe, concentrated at two transition points beneath a roadway. Each transition connected similar-sized corrugated metal pipe (CMP) to concrete pipe, creating imperfect connections that allowed groundwater to enter the system. ODOT required a trenchless repair solution capable of sealing these complex transition joints without excavation or disruption to traffic.

Engineered Solution

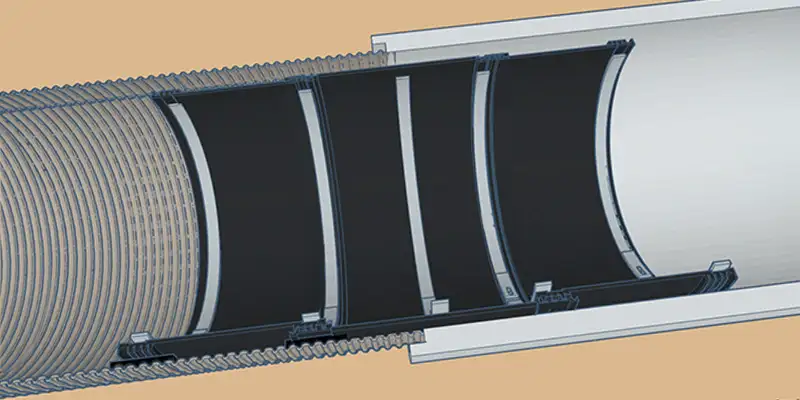

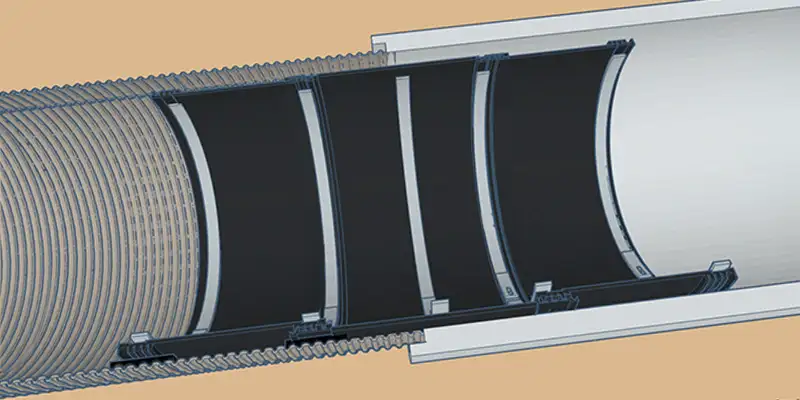

HydraTech engineered a custom HydraTite® Internal Pipe Joint Seal solution to accommodate the unique transition conditions. Each repair utilized interlocked seal sleeves, consisting of a double-wide (DW) inner rubber sleeve and a pair of extra-wide (EW) outer rubber sleeves.

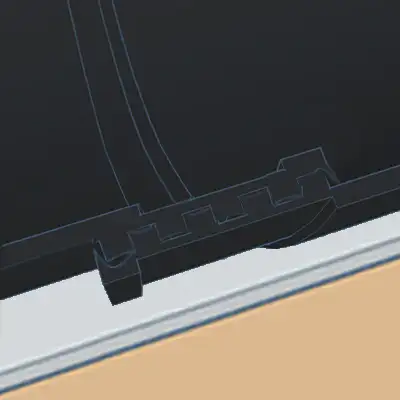

The seals were equipped with five 4-piece stainless steel retaining bands, allowing greater adjustability and uniform compression across the transition. The outer EW rubber was manufactured ¾ inch smaller in diameter to nest securely atop the DW seal, while one set of retaining bands was fabricated 1 inch smaller in diameter to ensure proper clamping over both overlapping layers.

Scope

HydraTech’s two-person field crew installed the custom-manufactured, interlocking HydraTite® seal sleeves. On the corrugated side of each transition, Pro-Stick® was applied to fill corrugation valleys and create a unified sealing surface prior to installation. The extra-wide outer seals were installed with the rubber ribs facing the pipe wall, while the double-wide inner seal was inverted so its ribs faced outward toward the pipe interior. The opposing ribs were pressed together.

Retaining bands were expanded within all designated channels of the extra-wide rubber sleeves, with the final retaining band installed over the center of the double-wide seal. A single intruding bolt at one joint was safely cut back to allow proper seal placement.

During installation, the crew identified an additional compromised joint on the corrugated side of one transition. The additional joint was repaired by first filling corrugation irregularities with Pro-Stick®, followed by installation of a custom 59.5-inch extra-wide HydraTite® seal secured with two 2-piece stainless steel retaining bands. All work was completed over two days, working onsite, with all joints successfully sealed.

Solution

All repaired joints were successfully sealed, eliminating infiltration. The HydraTite® system restored watertight integrity across both corrugated-to-concrete transitions and the additional compromised joint, without excavation or traffic disruption. This project demonstrated HydraTite®’s ability to adapt to complex transition geometries, manage dimensional variability, and deliver long-term performance using custom-engineered trenchless solutions.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature