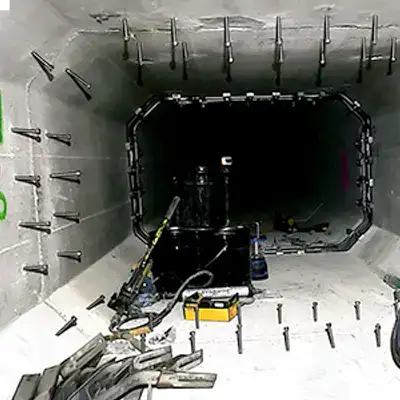

Installing Box Seals To Rehabilitate A Storm Drain Sump

HydraTite® (Internal Joint Seal System)

Market

Stormwater

Challenge

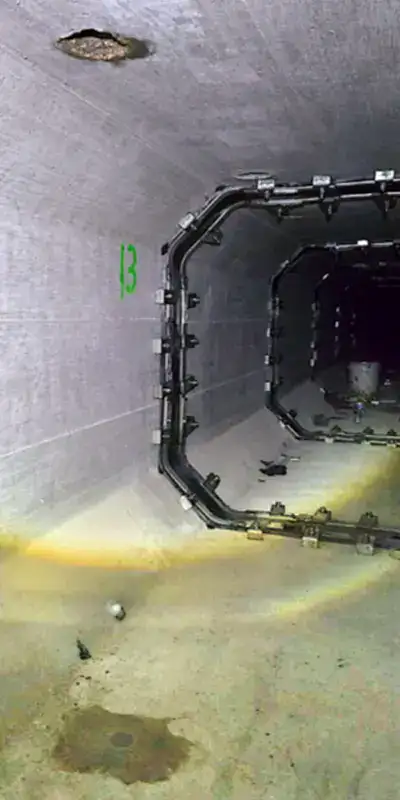

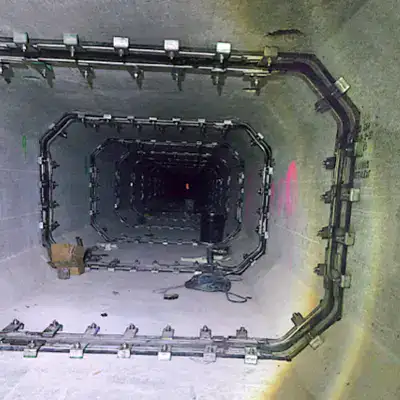

A newly installed storm drain sump that ran along the side of a levee failed its pressure test. Infiltration at the joints threatened the integrity of this box-shaped concrete pipe. A targeted repair was needed, rather than replace the newly installed system.

Engineered Solution

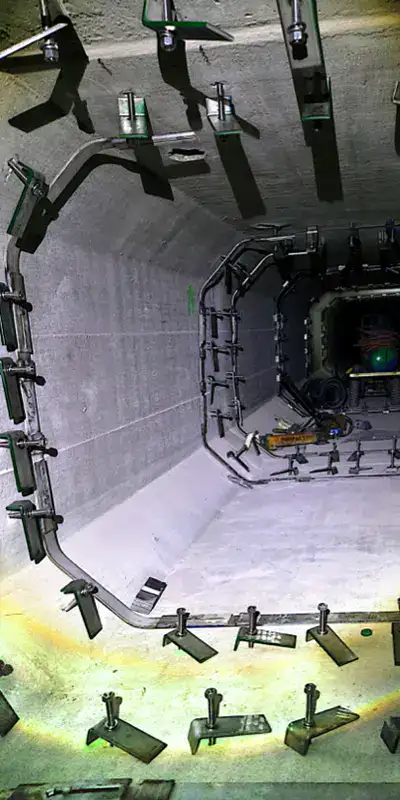

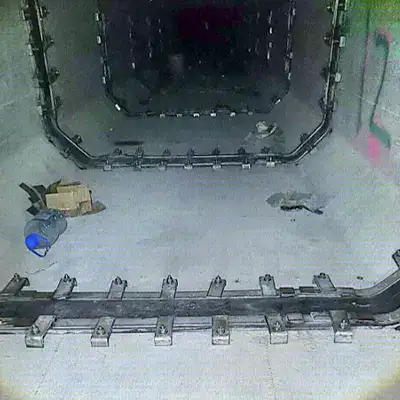

Standard-wide HydraTite Internal Pipe Joint Seals with anchors and hold-downs were the selected method to rehabilitate these joints without excavation.

Scope

One crew member positioned the materials near the joints and loosely constructed the retaining bands. The two other crew members installed the seals. First, the holes for the anchors were drilled on either side of the joints. Next, the debris from the drilling was brushed away and the anchors were driven into each hole. Then the rubber was positioned over the joint and the retaining bands worked inside the rubber’s designated channels. Butyl rubber was applied to the corners to aid the seal’s rubber in the transition over the corner. After that, the anchor plates were loosely installed so they lay atop the retaining bands. The retaining bands were then brought to pressure and the hold-downs were tightened against the bands. Each seal was air tested and if the anchors protruded beyond the hold-downs, they were trimmed back. The crew of 3 installed 17 seals in 8 onsite days.

Solution

This box-shaped storm drain sump was rehabilitated quickly without needing to be dug up. The infiltration was eliminated and these joints will be safeguarded from leaks for decades.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature