Working In Tight Quarters

HydraTite® (Internal Joint Seal System)

Market

Drinking Water

Challenge

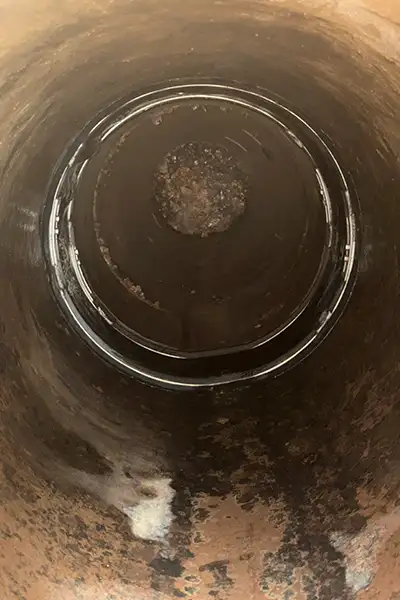

A New York water utility discovered a leak in a 24-inch ductile iron drinking water pipe running between a pumphouse and an elevated water tower. The pipe was located in a confined section of the system, making excavation and replacement costly and disruptive. The utility needed a potable water–approved repair solution that could eliminate leakage internally and extend the life of the pipe without service interruption.

Engineered Solution

HydraTech proposed using a standard-wide HydraTite® Internal Pipe Joint Seal, a mechanical trenchless repair method designed for pressurized and potable water applications. The seal’s EPDM rubber sleeve and stainless steel retaining bands provide a long-lasting, NSF/ANSI 61–compliant solution to stop joint leakage.

Scope

The prime contractor provided access to the pipe by cutting an opening near the leak site. HydraTech’s two-person crew took turns working in the 24-inch line to install a HydraTite® seal at the leaking joint. Once inside, the crew observed that the adjacent joint had become offset, prompting a second seal installation. The pipe’s internal liner was carefully chipped away near each joint to ensure continuous rubber contact around the pipe’s interior circumference.

Each seal was positioned over the joint, and two-piece stainless steel retaining bands were tightened on either side, locking the rubber in place. Because this was a potable water application, both seals were air-tested using the integrated test valve: air was pumped behind the rubber, a soapy water solution was applied around the edges, and the absence of bubbles confirmed a tight seal.

The crew successfully installed and tested both HydraTite® seals in one day within the confined space.

Solution

HydraTech’s trenchless installation provided a long-term, leak-free repair for the 24-inch potable water main in a single day—without excavation or service disruption. The HydraTite® system restored integrity to the ductile iron pipeline and protected the reliability of the community’s drinking water infrastructure.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature