Time Tested Products & Services

HydraTech products are thoroughly tested to provide maximum results for our customers, regardless of which industry your business falls into. Explore years of experience documented in over a hundred case studies. Discover both the common and most unique applications for our rehabilitation-focused products. All of our products and services offer a targeted repair, restoring defective points to avoid costly replacement. The installation process for these products requires minimal time and personnel but provides a long-term and watertight solution.

Reach Out Today To Learn More About Our Products

Email us using the contact page

Newest Examples Of Our Work

Targeted Repair

Fast Installation

Rehabilitate

Watertight

Pick A Product & Start Exploring

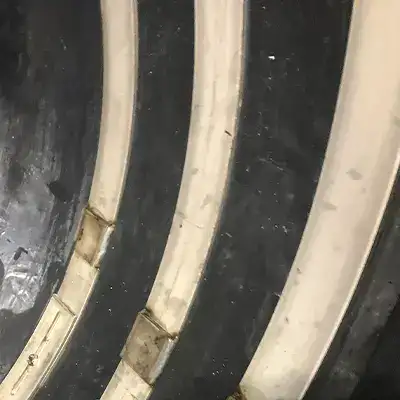

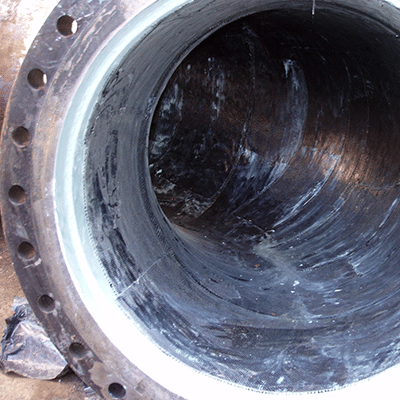

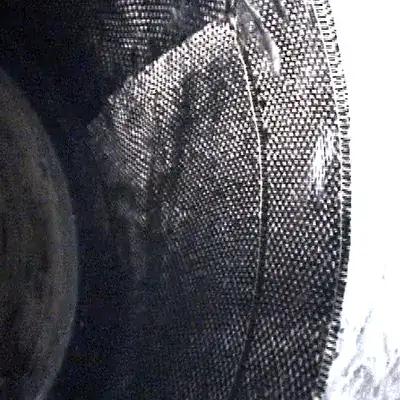

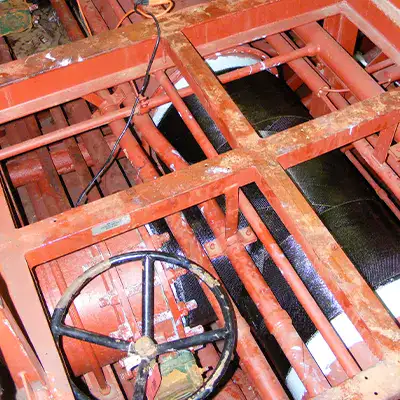

HydraTite offers a trenchless solution for leaking joints or other defective points in man-entry-sized pipes. HydraWrap is a carbon fiber fabric that provides a structural repair and protection against corrosion for pipes and other forms of infrastructure. HydraLine can function as a primer, filler, FRP binder, and chemical and corrosion-resistant coating. A mechanical packer can install HydraLock seals in non-man-entry pipes to eliminate leaks. WaterLine is an epoxy that can rehabilitate deteriorated potable water pipelines. HydraTech’s services go beyond the installation of products we manufacture. We offer a wide array of rehabilitation services, such as culvert cleaning, culvert field paving, fiberglass applications, and more!

Contact Us Today To Learn More About Our Products

Contact Us Today To Learn More About Our Products

Marine HydraWrap

Other Services

Marine HydraWrap

Other Services

Complete List of Case Studies

10-Foot Seals Installed At A Pump Station

13ft Diameter Reinforced Concrete Water Pipe

36-Inch Corrugated Polyethylene Outfall Pipe

48-Inch Circulating Water Line

66″ Culvert Repair Under NY Thruway

A Century-Old Pipeline Restored With HydraTite

Alleviating Multiple Points Of Concern

An Air Supply Line With Compromised Joints

An Emergency Repair For A Power Plant

Aqueduct Leaking On To Highway & Its Traffic

Box Seals Installed In A Coal Conveyor Tunnel

Bringing New Life To Aging Twin Culverts

Circulating Water Expansion Joint Repairs

Clearing Out Tuberculation & Installing 29 Seals

Cooling Water Piping Corrosion

Corrugated Metal Pipe Experiencing Infiltration

Cracked 42″ Diameter Gravity Drain

Custom Seals Installed Underwater

Debris Infiltration in Storm Drain

Demonstrating HydraTite & Preventing Future Sinkholes

Deteriorated Expansion Joint Repair

Deteriorated Joints in Outfall Pipe

Eliminating Leaks & Preventing More From Forming

Ensuring Bison Continue To Receive Water

Extending The Service Life Of A 186″ Pipe

Exterior Leaking in a Recirculating Cooling Line

External Crack to Expansion Joints

Failing Ductile Iron Pipe Joint

Failing Joints In An RCP Stormwater Drainage System

Groundwater Inflow Infiltration

Guarding A Transition Against Infiltration

Helping Prevent An Interstate From Collapsing

Installing All Over The County

Installing Box Seals To Rehabilitate A Storm Drain Sump

Installing During A Limited Window Of Shutdown

Installing HydraTite Around A Limestone Conveyor

Installing HydraTite In A Vertical Pipe

Installing HydraTite On A DOT Project

Installing HydraTite Seals In An Elliptical Tunnel

Installing Nine Irregularly-Shaped Seals

Installing Three Seals In A New Pipe

Interlocking Three Seals To Eliminate A Leak

Massive Box Seal Installed Over A Failing Expansion Joint

Newly Installed Leaking Ductile Iron Pipe

Overseeing A Seal Installation

Protecting A Municipality’s Water Supply

Providing A Permanent Fix For Storm Drain Leaks

Providing An Additional Layer Of Protection

Rehabilitating Defective Joints In An Elliptical Pipe

Reestablishing Proper Flow In Five Culverts

Rehabilitating 24″ Pipe With Separation At The Joints

Rehabilitating Nearly Every Joint In Two Culverts

Removing Deposits From Pipe Interior To Ensure A Proper Seal

Repairing A Recirculating Pump Line

Repairing A Water Main On A Tight Schedule

Repairing Drainage Pipes Under A Levee

Repairing Sanitary Pipe That Had A 6 Inch Hole

Repairing Two Joints In A 13-Foot Siphon

Restoring Pipe, Inside And Out

Restoring Structural Integrity After Seismic Damage

Sanitary Sewer Experiencing Wall Loss

Sealing 189 Joints In Three Box Culverts

Sealing A D-Shaped Drinking Water Pipe

Sealing A High-Pressure Water Main Joint In Arkansas

Sealing Critical Pipe Transitions to Stop Infiltration

Sealing Every Joint In A Pipeline

Sealing Every Joint In These Culverts

Sealing Over Cracks In A Box Culvert

Sealing Over Tears In HDPE Pipes

Sealing Stormwater Tanks For A Dublin Data Center

Sealing The Joints Between New Pipe And An Existing 84″ Water Main

Sealing Three Sides Of Large Tanks

Separated Culvert Joints Under A Busy State Route

Separated Joints In A Corrugated Metal Pipe

Six Joints In A 60-Inch Water Main

Stabilizing Roadway Drainage with HydraTite

Stopping Contaminants From Entering The Pipe

Stopping Infiltration At A Power Plant

Ten Seals Installed In Three Days

Terminating A Cured-In-Place Liner

Twenty Seals Installed In Twin Culverts

Two Box Seals Installed In Vertically Stacked Box Flumes

Two Days To Install Twenty-Two Seals

Water Main Blocking And Sealing

Applying Carbon Fiber To A 12” Diameter Pipe

Circulating Water Cooling Tower Deterioration

Condenser Water Boxes Structural Repair

Cooling Water Piping Corrosion

Cooling Water Piping Through Wall Leaks

Corroded High Pressure Gas Line

Defective Welds In A Hydroelectric Dam’s Water System

Midwestern HydroElectric Plant

Rehabilitating 24″ Pipe With Separation At The Joints

Rehabilitating A 36″ Surge Vessel

Rehabilitating A Long Section Of Pipe

Rehabilitating Four Risers In A Cooling Water System

Rehabilitation Of Ash Sluice Pump Intake Manifolds

Reinforcing Clamps On A Sanitary Pipe

Reinforcing Welds To Comply With ASME Design Codes

Repairing A 90″ Soil-To-Air Interface & Preventing Further Corrosion

Restoring Integrity to 10-Inch Cast Iron Pipe

Restoring Two Vertical Digester Pipes

Stopping Multiple Leaks at a Power Plant

Wrapping 12 Feet Of A Cast Iron Pipe

Wrapping An 18 Inch Pipe At A Pump Station

Marine HydraWrap

Cooling Water Supply Pipe Leaks

Installation On A Ferry On The East Coast of US

CFRP Repair Applied To Piers Beneath A Gas Tank

Spalling Culvert – Concrete Patch Repair

Hopple Street Bridge – Carbon Fiber Wrap

Increasing The Existing Pier Cap’s Shear Capacity

Pier Cap Repair – Carbon Fiber Wrap

Repairing And Reinforcing The Markland Bridge